R.K Enterprises

25 Years Of Undefeated Success

Achieving 25 years of undefeated success in Manufacturing field is a remarkable feat, showcasing not only consistent excellence but also resilience, adaptability, and sustained innovation. Whether it’s in business such a milestone speaks volumes about the dedication, skill, and strategic thinking of those involved. It’s a testament to their ability to consistently outperform competitors, navigate challenges, and stay ahead of the curve.

70+

Successfully Project Finished.

15+

Years of experience with proud

50+

Number of products

3

Number of factory

WHAT IS FORMWORK?

Formwork refers to the temporary or permanent molds into which concrete or similar materials are poured to give them a desired shape and structure. It’s essentially the framework or mold that holds the concrete in place until it sets and gains enough strength to support itself. Formwork is crucial in Manufacturing projects for creating structures such as walls, columns, beams, slabs, and more. It can be made from various materials like wood, steel, aluminum, or plastic, depending on the specific requirements of the project. Formwork needs to be strong, rigid, and properly supported to withstand the pressure exerted by the wet concrete and to ensure the desired shape and finish of the final structure.

WHY IS FORMWORK IMPORTANT?

Formwork holds a critical role in Manufacturing due to its multifaceted contributions. Firstly, it facilitates the realization of precise shapes and structures as envisioned by architects and engineers, ensuring that the final product meets design specifications with accuracy. Secondly, it provides essential support for freshly poured concrete during the curing process, safeguarding against deformations and collapses, thus maintaining structural integrity. Moreover, formwork contributes to quality assurance by controlling the casting environment, minimizing the risk of defects such as cracks or uneven surfaces.

Types of formwork

Types 0f Formwork

Various types of formwork systems are employed based on the specific requirements of the project. Here are the main types of formwork:

Our Services

RK Enterprises form work , we specialize in providing top-notch formwork solutions for Manufacturing projects of all sizes. With our dedication to quality, safety, and efficiency, we ensure that your project is executed flawlessly from start to finish.

Formwork Design and Engineering

Our team of experienced engineers and designers creates customized formwork solutions tailored to meet the specific needs of your project. We utilize the latest technology and industry best practices to ensure optimal performance and durability.

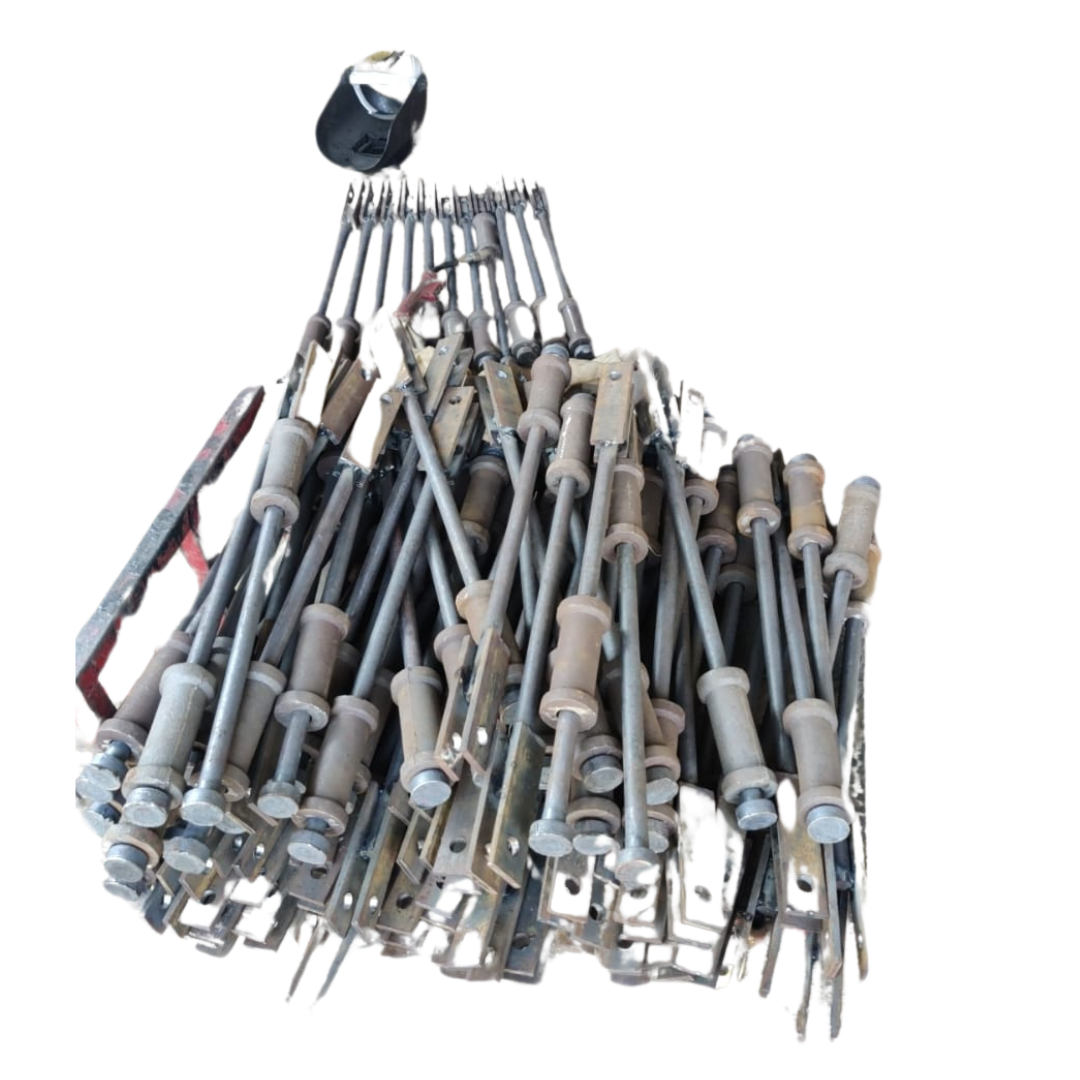

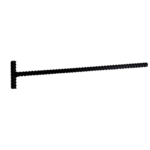

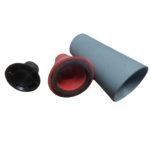

Formwork Fabrication

We have state-of-the-art fabrication facilities equipped to produce high-quality formwork components with precision and efficiency. Whether it's traditional timber formwork or modern modular systems, we deliver products that meet the highest standards of quality and reliability.

Formwork Installation

Our skilled installation teams ensure that your formwork is set up accurately and efficiently, allowing for smooth Manufacturing progress. We prioritize safety at every step of the installation process, adhering to industry regulations and best practices to mitigate risks and ensure a secure working environment.

Formwork Removal and Reuse

After the concrete has cured, our teams efficiently dismantle the formwork, leaving behind a clean and organized site. We carefully inspect and evaluate the formwork components for potential reuse, helping to minimize waste and reduce project costs.

Our Recent Project's

Trusted by over

100+ Clients

ENINEER

Design formwork systems for walls, columns, pilasters and climbing formwork systems. Assists in forecasting material needs for formwork, shoring and reshoring. Good knowledge about Civil Engineering

DESIGNER

Responsible for preparation of layouts, 3D model and other CAD related drawings/document which are required for product fabrication.

ARCHITECT

A formwork architect specializes in the design and implementation of temporary structures used to support concrete during Manufacturing. These structures, known as formwork, are essential for shaping and holding freshly poured concrete until it sets and gains sufficient strength to support its own weight and any additional loads.

MANAGER

A formwork manager is a key professional responsible for overseeing all aspects of formwork manufacturing within a construction project. Their role is crucial in ensuring that the formwork systems are efficiently designed, installed, and maintained to support concrete structures during construction.